According to IHS Markit, an information service provider, almost 75 million cars worldwide were fitted with lock sets in 2020. Huf accounted for 20 million of lock sets including car key and locking cylinders. That makes us the global market leader in lock sets - and we have been for decades. It is therefore no secret that Huf is the first port of call for car manufacturers when it comes to car keys and lock sets. That’s the way it’s always been. But very few know about one of the consequences of this consistent record of maintaining the pole position, which is that almost all cars worldwide now benefit from Huf expertise.

When you think

of car keys,

think Huf

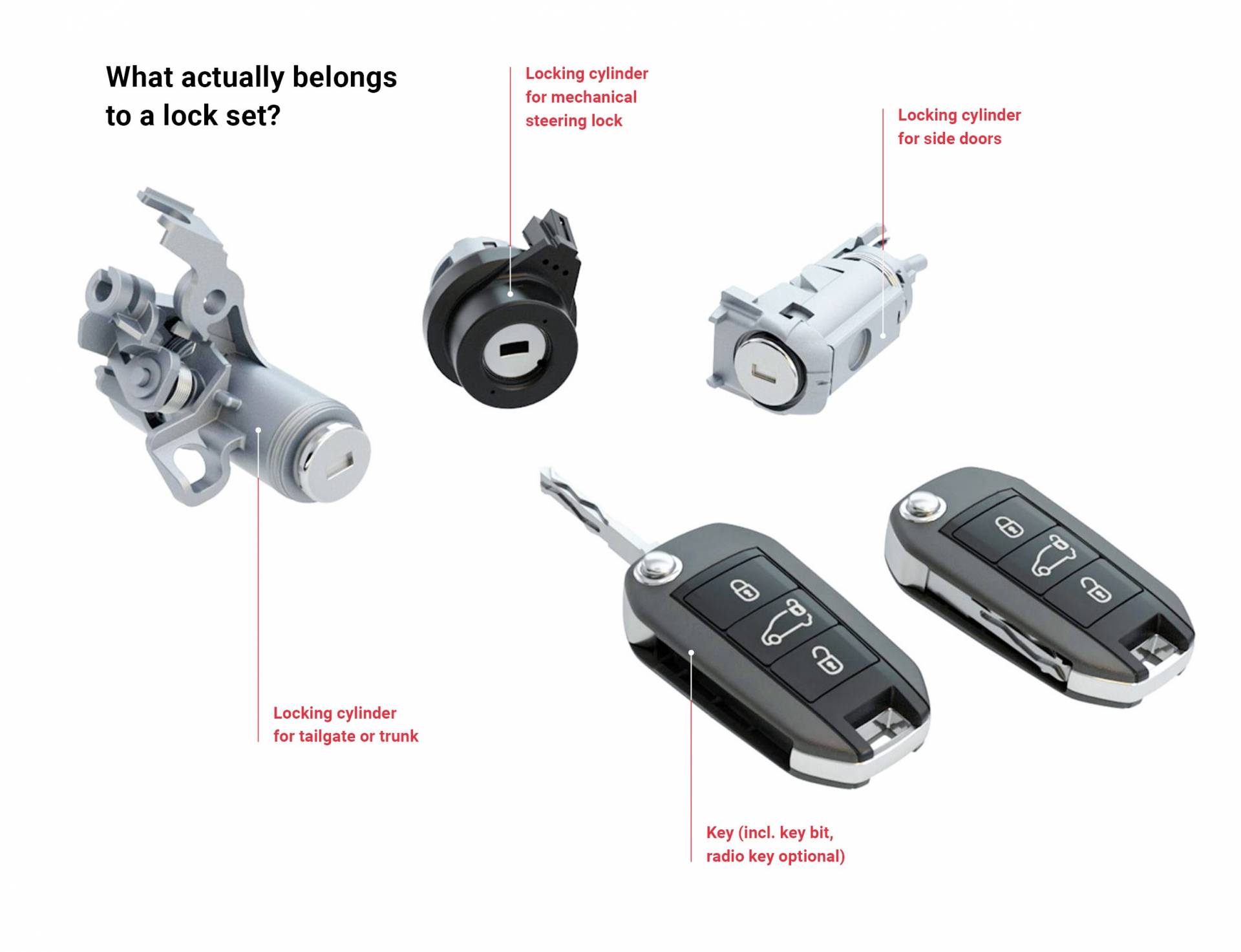

When it comes to lock cars securely, Huf is right at the top of the list for any car manufacturer. The specialist for secure car access and authorization is the global market leader in lock sets. The lock sets, consisting of car keys and locking cylinders installed in doors and steering columns, contribute to the high level of theft protection. However, the final product is not the only way in which Huf provides its customers with first-class solutions to problems. Huf also sets new standards in the development of digital key clouds and highly automated global production.

For about 100 years: Lock sets made by Huf protect cars from thieves

Ever since cars first had to be protected from thieves in the 1920s, Huf has made it its mission to make life as difficult as possible for thieves and has led the charge in developing locking systems with numerous innovations and first-to-market products.

Huf grow together with the automotive industry and has become a top supplier in the 1960's and equipped almost all models in Germany with locking systems, including iconic cars such as the Opel 4 PS, BMW Isetta, VW Beetle, and Mercedes 180 D (W 120). During Germany’s post-war economic boom, Huf played a major role in car keys taking on multiple functions. Previously, each lock on the vehicle had to be opened with a separate car key, but a single car key could now be used for the side doors, trunk, and ignition.

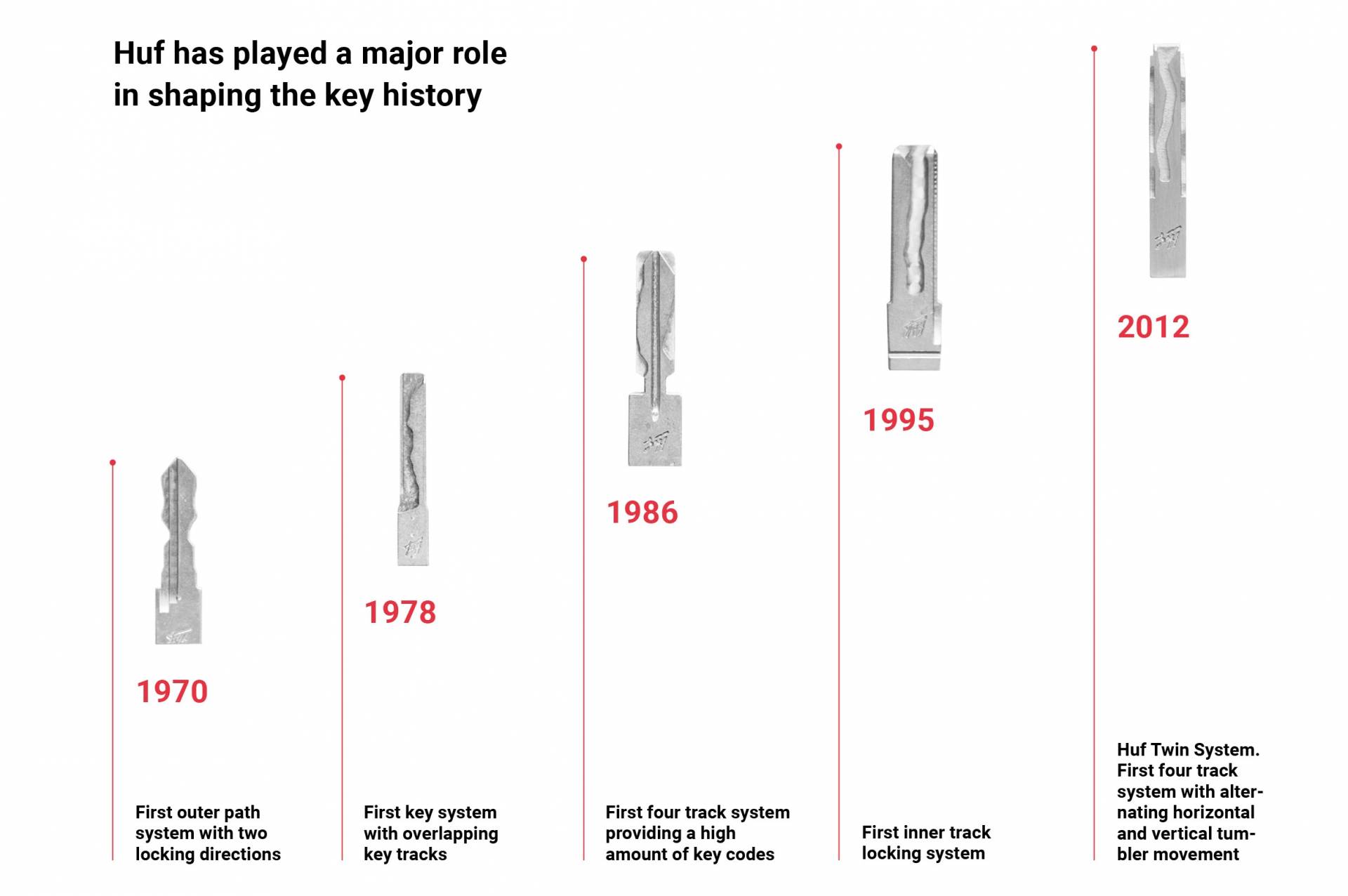

In 1970, Huf took another step forward in terms of convenience and introduced the reversible car key system. Unlike with previous car keys, it was no longer necessary to worry about which way around the car key was when it was inserted into the locking cylinder, as the notches were now rotationally symmetric and therefore identical on both sides. In 1978, Huf continued this development and milled the codes directly into the car key bits. The two-track system also meant the end of the age-old picklock’s practice of copying car keys by creating templates of their sides.

In the 1980s, when a trend emerged among car manufacturers of pursuing their own paths with customized locking systems, Huf became a sought-after development partner and supplier all over the world. VW, Toyota, GM, Hyundai, Ford, Mercedes, BMW, Peugeot, Renault, Opel, Volvo - Huf car locking technology could be found in all major platforms worldwide. That has continued many times over into the present days.

Car keys and locking cylinders with internal-track system increased theft protection

In 1995, Huf set another standard with a new development, presenting the first internal-track locking system. Unlike the systems known up to that point, the guard locks were no longer guided over the “hills and valleys” of the car key, but had to wend their way through a track. This forced guidance not only considerably improved security against theft, but also improved reliability. The downside of outward-facing car key bits is that they can pick up crumbs, lint, and other dirt in pockets and purses. When the car key is then inserted into the locking cylinder, the uninvited passengers shift the guard locks into the wrong positions, and the lock fails to grant access.

Further benefits of the innovative car locking (and of course unlocking) system that Huf introduced at the time include the fact that the exceptionally precise guide tracks were extremely difficult to duplicate and also allowed for a much higher number of different lock codes. That meant that Huf could also fulfill a customer request to offer different lock codes and yet similar car key designs for all brands in the VW Group. Other manufacturers, such as BMW, Rolls-Royce, Peugeot and Hyundai, were to follow, likewise reaping the benefits of the invention made by Huf.

Huf Twin System - the world’s most secure locking system

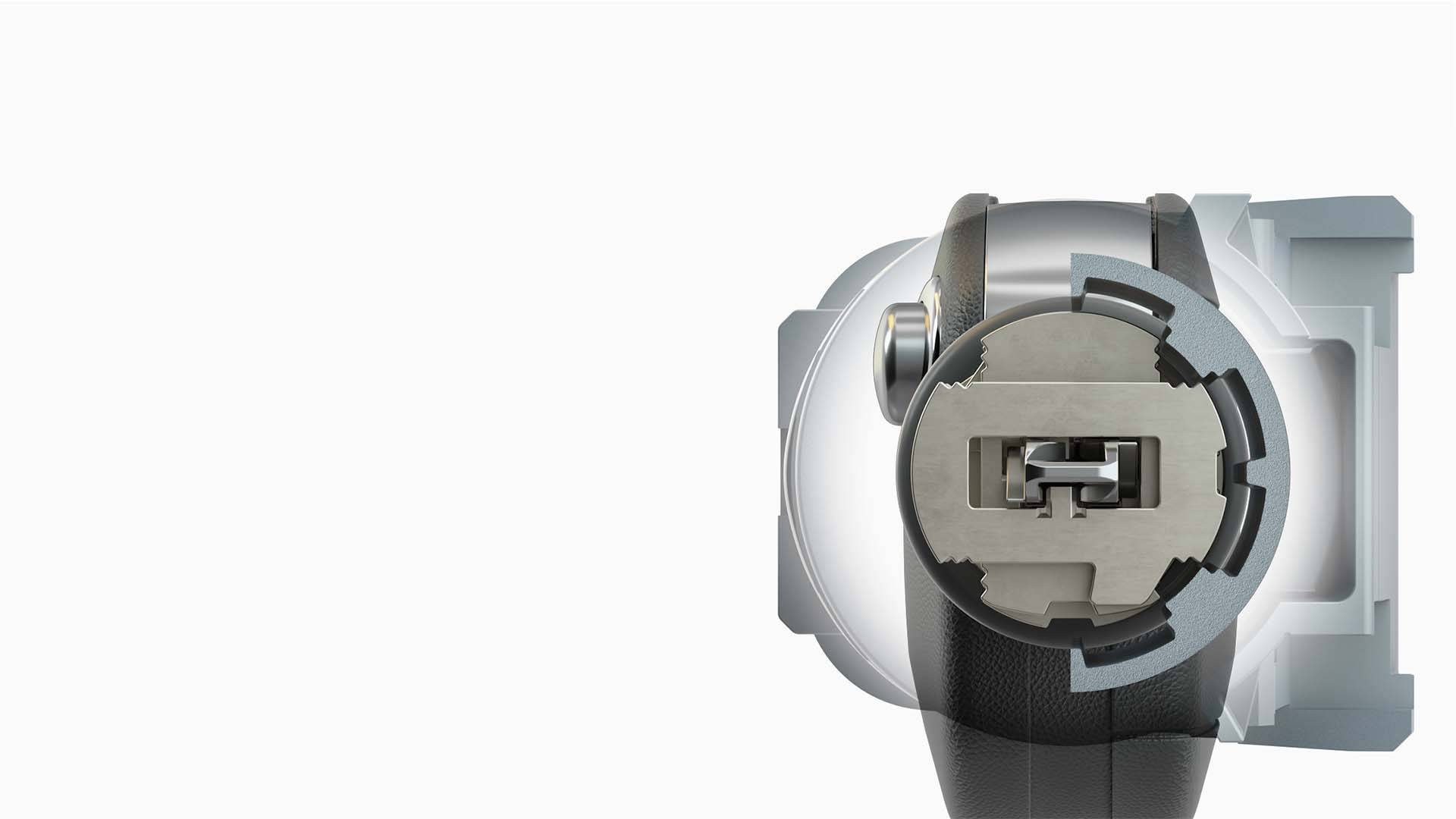

The race against ever more-creative thieves continued, and Huf was always one step ahead. Around 20 years later, one of the biggest automotive companies benefited from another Huf innovation that was to play a big part in the significant improvement in theft prevention for all the carmakers’ vehicles. The new locking system was based on the Huf Twin System, an in-house Huf development. The Huf Twin System is the world’s most secure locking system for cars and the innovative supplier holds almost all patents for it. Together with its client Huf developed based on the Twin System a new locking system that is equipped since 2014 in all cars of the automotive group, including all sub-brands and their cars and provides them with the best theft protection you can get worldwide.

What makes the Huf Twin System special is that all four sides of the car key shank are individually coded. There is also the fact that Huf has combined the best characteristics of the most secure lock technologies in one lock set system. Two opposing sides feature the already very secure internal-track technology. The other two sides perform precisely the reverse function. On these, the tracks are not milled but are laid on top, with these raised sections running through the grooves in the guard locks and thereby shifting them into the correct positions.

That means that anyone trying to pick the lock needs to be well versed in a range of different techniques to get the guard locks in the car locking cylinder - as many as ten of them - into their respective positions on two axes and into the right insertion position as well. And because the guard locks project into the locking cylinder from all four sides, thieves have very little room to insert their tools and decipher any of the up to 80,000 lock codes.

Harley-Davidson also recognized the benefits of this locking system for its motorcycles - coveted by many, sadly including thieves - and placed an order with Huf in 2015 for the development of an especially compact locking cylinder for maximum theft prevention. With the Harley locking system, Huf removed the separators and allowed the guard lock plates to run directly adjacent to each other like a sandwich. This very intricate mechanism requires exceptional precision in the manufacturing process, which Huf was able to ensure along with speed and excellent quality thanks to its many years of experience.

From Huf Mexico to the world: Harley-Davidson motorcycle keys benefit from Huf Twin System.

Four eyes see more than two: In the quality process all products will be checked to fulfill the high standards.

Hidden innovations: So-called emergency keys are often inside of remote control keys that can be used to open cars by pressing a button or hands-free.

Huf sets standards in lock set development and production

With the Huf Twin System, Huf offers the most secure means of protecting a car against theft. In addition, further lock sets with internal-track systems that Huf has played a leading role in developing over previous decades are sold worldwide. Almost all keys all over the world that unlock car doors and start engines or, unbeknown to some drivers, are hidden in remote control keys as backups, feature know-how from Huf. When car manufacturers are planning to develop new car locking systems, they generally consult Huf for advice. On numerous occasions, Huf has also gone on to secure the manufacturing contracts for car keys.

The specialist in car locking systems has a history dating back almost a hundred years in manufacturing as well, which means that it can boast plenty of experience in delivering top-notch quality. These days, Huf produces lock sets for a range of car manufacturers at ten plants on four continents. Velbert (Germany), Yantai (China), Puebla (Mexico) and Tondela (Portugal) produce the highest volumes, at up to 100,000 lock sets per week. The largest plants in the Huf production network also include El Burgo de Osma in central Spain, where employees work around the clock in three shifts every day to make lock sets. “For any global assembly network, it is essential for all the individual parts to maintain the same production quality,” says Georg Rosenkranz, Plant Director for Operations at Huf Espana.

“At Huf, we have valued standardization of single-part manufacturing for years because that way, each location delivers identical quality. Various sites have built up outstanding expertise in this respect. The molds for the locking cylinders, for example, come from Spain, and we supply them to all Huf Group sites. This high degree of standardization means that we can plan our resources for lean production as effectively as possible. The enormous amount of know-how that Huf has accumulated over decades plays a crucial role in all these processes,” says Georg Rosenkranz.

lock sets per week produced in Velbert, Yantai, Puebla and Tondela.

This experience is clear right from development and planning of production processes once a customer has placed an order. The Industrial Engineering team at Huf knows all about potential pitfalls in manufacturing and uses reliable planning of workflows and processes to cut defect rates. At the same time, the experts know from numerous successful projects where it is possible to save on resources to optimize production costs. “It is thanks only to the incredible cooperation between the teams, from Industrial Engineering to Quality Management, that we are able to provide our customers with first-class products at an excellent price/performance ratio. In the process, we focus not on what is necessary, but on what is possible and what makes sense from our perspective. To give an example, our internal tolerances for lock set production extend down to 0.05 mm, considerably smaller than manufacturer specifications,” says Rosenkranz.

Huf car key service: ready for customers 24/7

However, the constant pursuit of perfection at Huf does not end when a lock set is delivered to a car manufacturer, which receives the product through a just-in-time process. As a long-standing partner to car manufacturers, Huf has a special responsibility that calls for speed and precision: reproducing lost keys and locking cylinders, which can be destroyed as a result of accidents, for example. Thanks to its wealth of knowledge and global production network, Huf offers a Repetitive Single Order Service that is very much valued by carmakers. Within 24 hours of receiving an order, Huf can reproduce and send out – worldwide – the specially coded lock set for the vehicle in question.